Centrifugal Casting

Features of Non-ferrous Casting

1. Compared to sand casting, this centrifugal casting has the advantages of higher compactness and mechanical property.

2. This casting is beneficial to environmental protection, and the productivity of casting products is high.

3. The centrifugal casting process is suitable for the copper, aluminum, iron, stainless steel, alloy and other materials.

4. The non-ferrous casting products can be made in almost any length, thickness and diameter.

5. Different wall thicknesses can be produced from the same size mold.

6. This centrifugal casting is resistant to atmospheric corrosion.

7. Only cylindrical shapes can be produced with this non-ferrous casting process.

Description

Centrifugal casting utilizes centrifugal cast tube to manufacture roller sleeve shaft and other kinds of wheel castings. This non-ferrous casting can be divided into horizontal type and vertical type.

This casting is a metallurgical manufacturing process that is typically used to cast thin-walled cylinders. Unlike other non-ferrous casting, this casting process is used to produce stock materials in standard sizes for further machining, rather than shaped parts tailored to a particular end-use.

In centrifugal casting, a permanent mold is revolving continuously about its axis at high speed as the molten metal is poured. The molten metal is centrifugally thrown towards the inside mold wall, where it solidifies after cooling. The non-ferrous casting is generally a fine-grained casting with a high precise outer diameter, owing to cooling against the mould surface.

Images Information

|

Material: ZCuCr0.5

Technology: Centrifugal casting-forging process-heat treatment

Application: bearing segment

Specification: OD700xID300xL350 |

Material: ZCuCr0.5

Technology: Centrifugal casting-forging process-heat treatment

Application: shaft sleeve

Specification: OD800xID600xL700 |

Material: T2

Technology: Centrifugal casting-forging process-heat treatment

Application: shaft sleeve

Specification: OD400xID275xL380 |

Material: ZCuSn5Pb5Zn5

Technology: Centrifugal casting

Application: shaft sleeve

Specification: OD550xID450xL500 |

Material: ZCuSn5Pb5Zn5

Technology: Centrifugal casting

Application: gland ring

Specification: OD1060xID910xL200 |

|

Material: ZCuPb15Sn8

Technology: Centrifugal casting

Application: oil seal ring

Specification: OD320xID250xL350 |

Material: ZCuPb15Sn8

Technology: Centrifugal casting

Application: lubricating shaft sleeve

Specification: OD320xID250xL200 |

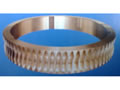

Material: ZCuSn10P1

Technology: Centrifugal casting

Application: wear resistant gear

Specification: OD800xID600xL150 |

|

|

As a professional non-ferrous casting manufacturer and supplier in China, we have the capacities to carry out centrifugal casting, sand casting, gravity casting, shell casting, low-pressure casting, forging process as well as precision machining. We possess advanced equipments, such as tensile machine, gravity casting machine, low-pressure casting machine and centrifugal casting equipment, heat treating equipment, 5-axis and 4-axis advanced machining centers imported from Germany.

Related Products

- Coated Sand CastingThe resin sand casting equipment consists of shell core machine, core shooter, casting machine, advanced coated sand formula and manufacturing technique.This sand casting process is suitable for the production of cars, tractors and hydraulic parts. The molding materials include copper, iron and steel....

- Sand CastingSand casting, as the most widely used casting process, utilizes the removal of sand molds to form metal components. This type non ferrous metal casting process can use any alloy material, such as aluminum alloy, copper alloy, magnesium alloy, alloy steel, carbon steel, nodular cast iron, gray cast iron, stainless steel and titan...

English

English Français

Français Deutsch

Deutsch